The combination of excellent hot hardness and good thermal shock resistance makes H13 an excellent choice for hot work applications. H13 is known for its good thermal shock resistance which reduces thermal fatigue cracking from repeated heating and cooling cycles. H13 tool steel is a chromium-molybdenum hot-work steel that is characterized by high hardenability, excellent wear resistance, and excellent hot hardness.

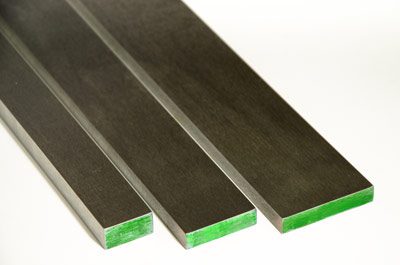

We sell D2 tool steel in both rounds and flats. The typical applications for D2 tool steel are Rolls, Punches, Blanking Dies, Forming Dies, Trimming Dies, Shear Knives, Planer Blades, Knife Blades, and more.

S7 tool steel for sale rectangular bar upgrade#

D2 is used for the parts that require absolute highest wear/abrasion resistance such as a long run productions parts and is an upgrade over A2. While D2 is very wear and abrasion resistant it is not as tough as alloyed steels and is very sensitive to heat treatment. The high chromium content of D2 gives it mild corrosion resistance properties in the hardened condition. An advantage of A6 steel is its lower hardening temperature range of 1500 – 1600 ☏, that is typically only found in oil-hardening steel grades.ĭ2 tool steel is a high carbon, high chromium, air-hardening, cold work tool steel that is characterized by excellent wear and abrasion resistance properties. The chemical composition of A6 steel has a higher manganese, lower chromium and carbon content than A2 steel.

S7 tool steel for sale rectangular bar free#

The typical applications of A2 tool steel are punches and dies, dowel pins, precision tools, gauges, shear blades, slitters, industrial knives, and more.Ī6 is an air-hardening, non-deforming, decarb free tool steel that is characterized by deep hardening, low distortion, moderate toughness and wear resistance. A2 is an upgrade over O1 oil-hardening steel when higher toughness, higher wear resistance, and lower distortion are required. A2 tool steel is composed of a high carbon content which allows it to be deep hardened in order to minimize distortion. A2 is characterized by good machinability, good toughness, excellent dimensional stability in heat treatment, and high wear resistance. This material is prepared over-sized to finish for the customer, typically (+.020/.040”) on the thickness, unless specified otherwise.Ī2 – A6 – D2 – H13 – O1 – L6 – S1 – S5 – S7Ī2 tool steel is an air-hardening, medium-alloy, cold-work tool steel that has 5% chromium. Tool Steels are also used in production of injection molds. They are used often for cutting, pressing and coining other metals and materials. Tool Steels are carbon and alloy steels known for their exceptional hardness and resistance to abrasion, which is why they are typically used to make into tools.

0 kommentar(er)

0 kommentar(er)